The ADAPT tool:

Remove large, heavy and expensive equipment from your equipment list

ADAPT is a product that simplifies subsea tubing hanger operations by eliminating equipment and operational and HSE risks.

Removing the umbilical from the equipment list

Traditionally an umbilical from surface is required to operate the Tubing Hanger Running Tool (THRT) during subsea Tubing Hanger (TH) installation or retrieval.

ADAPT tool is mounted on top of the existing THRT and operate the THRT hydraulic functions without the use of an umbilical to surface.

The video below illustrate the traditional setup and what the ADAPT tool makes redundant (red).

By pre-installing ADAPT tool and THRT to tubing hanger in the workshop the Tubing Hanger Handling Tool (THHT) and C-plate become redundant.

Additionally, spooling unit, jumper, HPU/control unit, sheave wheel, umbilical clamps, baskets and other equipment is also removed.

Different THRT adapters allow the ADAPT tool to interface with all SPS companies THRT’s, ensuring seamless integration with different tubing hangers and associated equipment.

ADVANTAGES

Cost Saving

• Reduced operational time

• Reduced equipment need

• Reduced mob / demob scope

• No personnel offshore

HSE

• No personnel in red zone

• Less rigging and handling

• Reduced shipping

• Re-use of existing THRT

Operational

• Remove a lot of large and heavy equipment

• Pre-install tubing hanger from workshop

• Improved well control

• Increased weather window

Why us?

• Small, agile, solution-oriented company

• Strong in-house competence on subsea and completion

• Flexible support and delivery model

• Delivery through SPS supplier

How does it work?

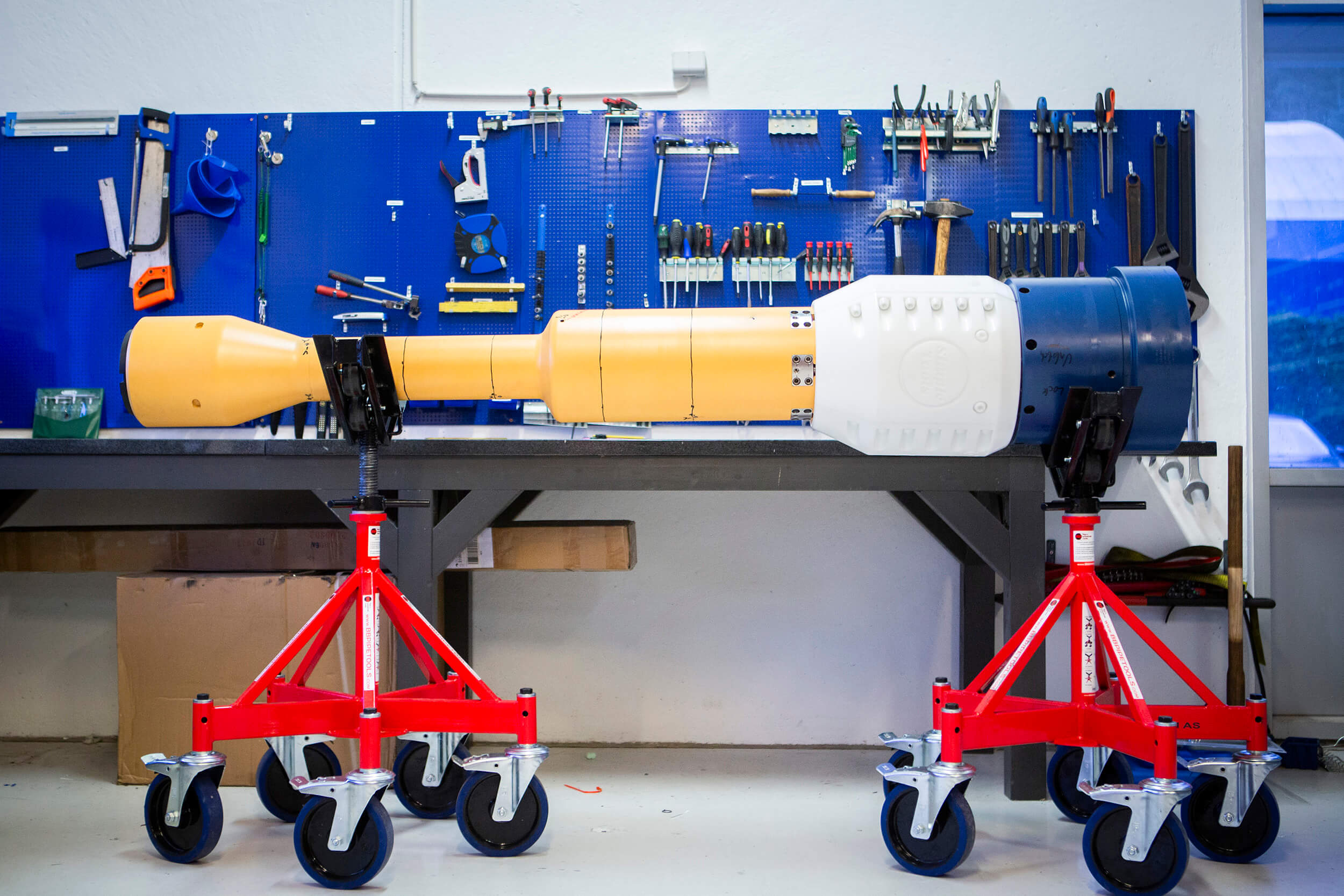

- Make-up ADAPT to THRT and TH and test onshore

- Ship to location and move to drill floor as one assembly

– No need for Tubing Hanger Handling Tool or C-plate - Make-up TH to completion string

- Run in hole on pipe and land TH

– No umbilical, clamps or sheave - Operate THRT functions sequentially by closing BOP rams and pressurize different cavities

– ADAPT offers redundancy and fail-safe mechanisms - POOH

– ADAPT can be redressed offshore

One system, different applications

The ADAPT tool can be used for both installation and retrieval of tubing hangers and associated equipment (ITC, SLC etc.).

Based on the operation, different ADAPT configurations may be needed. Below is a description of the various ADAPT tools that we offer.

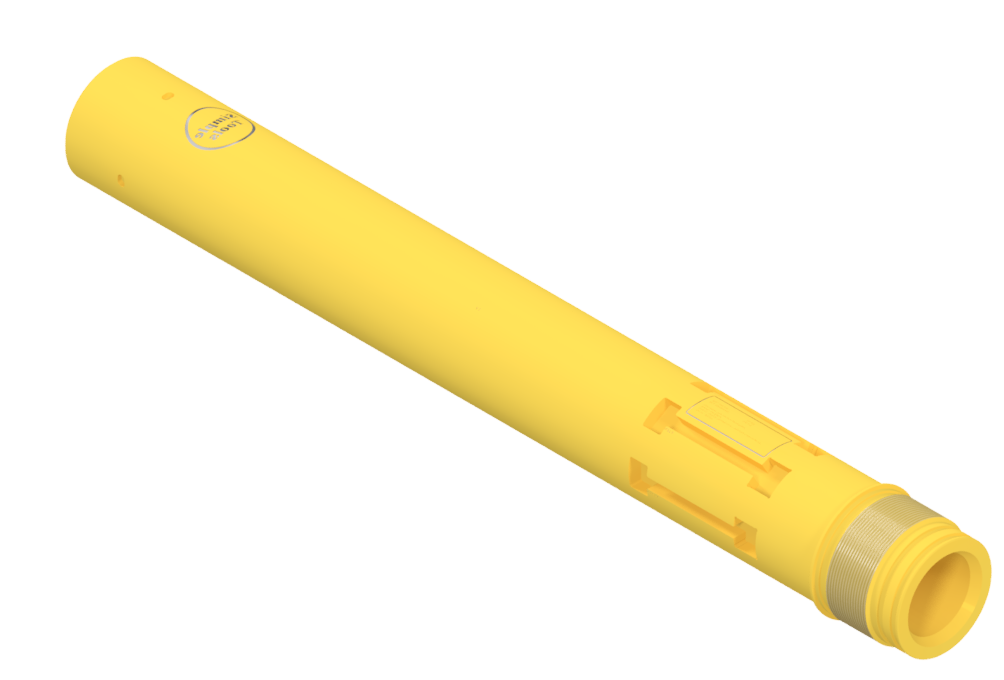

ADAPT: Standard Tool

The Standard tool is for Simplified Landing String (SLS) applications. Read more...

In this application Tubing Hanger Crown Plugs (THCP) are either pre-installed in the TH or installed separately.

The tool inner diameter allows for wireline access and outer diameter is compatible with standard BOP pipe ram configurations.

The standard tool can be NORSOK R-002 certified for lifting and used for both installation and Plug & Abandonment (P&A) applications.

ADAPT: HP Riser Tool

The HP riser tool is for applications where the BOP is placed on surface (dry BOP). Read more...

With a surface BOP there are no rams available to close around the ADAPT. Therfore this tool is operated by a custom logic system that allows for remote operation of the THRT without the sequential use of BOP rams.

The short length (<1m) makes this tool ideal for offshore handling and it can easily be configured between workover riser (WOR) and drill pipe (SLS) deployment.

This tool is also fitted with full-bore inner diameter to allow for tubing hanger crown plug installation or retrieval.

The HP riser tool can be NORSOK R-002 certified for lifting and used for both installation and Plug & Abandonment (P&A) applications.

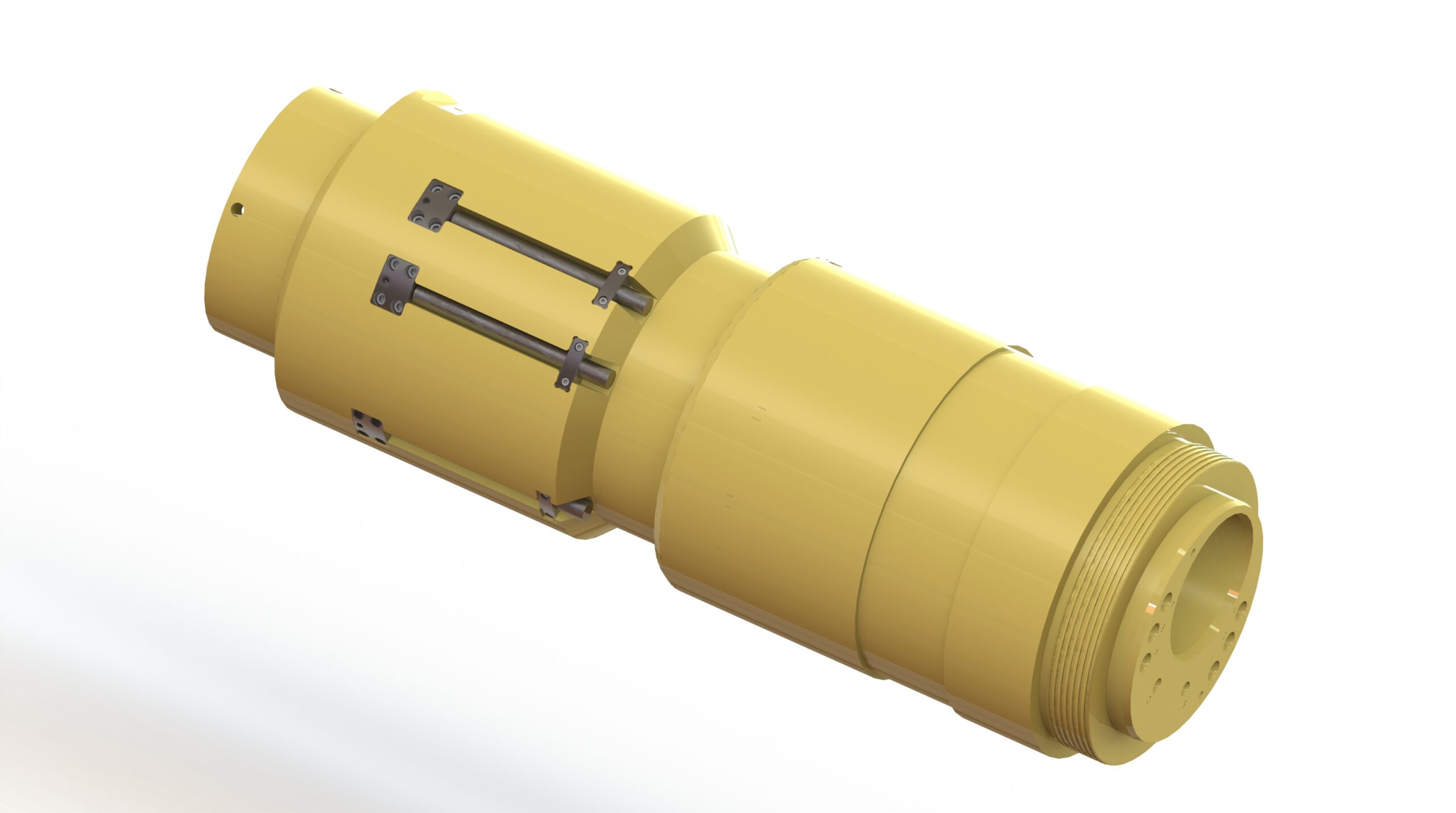

ADAPT: Big Bore Tool

The Big Bore tool is for workover riser (WOR) applications. Read more...

The Big Bore tool is for applications where it is required to install or retrieve Tubing Hanger Crown Plugs (THCP) through the landing string, typically a workover riser (WOR). The inner diameter is equal to, or larger than, the inner diameter of the THRT allowing full bore access.

This tool is configurable for 9 5/8″ or larger rams, or a combination with a a custom logic system that allows for remote operation of the THRT.

The BigBore tool can be NORSOK R-002 certified for lifting and used for both installation and Plug & Abandonment (P&A) applications.

Technical Data for ADAPT (Standard tool)

The values in the table below are general properties, and may vary from project to project.

|

Property Comment |

Value Metric | Value Imperial |

|

Max. Outer Diameter |

Ø 266 mm |

Ø 10 1/2 in |

|

Min. Inner Diameter |

Ø 95 mm |

Ø 3 3/4 in |

|

Working pressure |

690 bar |

10,000 psi |

|

Max. water depth |

3000 m |

10,000 ft |

|

Overall Length |

Project Specific |

|

|

Top connection* |

6 5/8″ FH Box (Interface to Crossover handling pup) |

|

|

Bottom Connection** |

10in Stub ACME Pin (Interface to THRT adapter) |

|

|

Drill pipe shank size |

5 1/2in, 5 7/8in or 6 5/8in |

|

|

BOP ram configuration |

5 1/2in to 9 5/8in – Project specific |

|

|

Max. THRT functions*** |

9 |

|

|

* ADAPT is delivered with customer specified thread/ crossover handling pup in top ** ADAPT is delivered with THRT adapter in bottom to interface with THRT *** ADAPT valves are configured to specific THRT |

||

Case Studies

Repsol – Yme Beta North – Installation Experience

New and innovative solution for subsea completion equipment installation